Oct 23, 2025

Top Applications of Famous Overhead Insulated Cable in Utilities

As the need for steady and secure power transmission rises around the world, power companies look for options that provide both reliability and protection. Well-known overhead insulated cable stands out as a top pick for today's power setups. It gives better safety than old bare wires. These cables offer strength, fit with worldwide rules, and work well in many settings. That makes them a must-have for current power needs.

Key Features of Well-Known Overhead Insulated Cable

Overhead insulated cables use suitable materials for good power flow and toughness:- Conductor: Aluminum, copper, aluminum-alloy, ACSR or ACSR/AW for a great balance of strength and weight.

- Covering: Plastic polyethylene (PE) or linked polyethylene (XLPE), with protection from weather and sun.

- Working Heat: Built for 75°C or 90°C steady use.

- Rule Fit: Made to match GB/T 14049 (same as IEC 60502-2), NFC 33-209 (France), BS EN 50397-1 (EU), AS 3599 (Australia), NTC 5909 (Colombia) and ANSI/ICEA S-121-733(American).

Primary applications in Power Companies

City and Suburb Power Grids

- Safe setup in spots with lots of people.

- Small size lets it deliver power where room is tight.

Countryside Power Projects

- Holds up to wind, rain, and physical wear.

- Good for cheap growth of village and far-off grids.

Factory Areas and Business Sites

- Fits the ongoing power needs of plants, factories, and server rooms.

- Works with mid-voltage overhead power setups.

Spots with Plants and Trees

- Covering lowers shorts from tree brushes.

- Cuts down on regular plant cutting.

- Very useful in wooded and suburb green zones.

Beach and Wet Areas

- PE or XLPE covering guards against salt rust and damp.

- Lengthens life even in harsh beach weather.

- Solid pick for dock towns and island power lines.

Short-Term or Crisis Power Needs

- Easy to set up for storm fixes or building jobs.

- Bendy setup without big pole builds.

- Gives sure power in key moments.

Comparison: Bare Wires vs. Well-Known Overhead Insulated Cable

| Aspect | Bare Wires | Well-Known Overhead Insulated Cable |

| Safety | Bigger chance of shocks | Better guard with covering |

| Upkeep | More upkeep required | Less upkeep required |

| Setup | Needs wide space | Small, saves room |

| Life Length | Open to rust and weather | Sun & weather-proof covering |

| Price | Cheaper at start | More up front, but less over time |

Challenges and Things to Think About

While overhead insulated cables bring many advantages, power companies need to handle a few issues:- Power Match: Make sure cables fit right with holders and spacers for the set voltage.

- Price Points: Start cost beats bare wires. But savings hit from fewer breaks and less ongoing care.

- Rule Fit: World standards are there. But local changes stay. Buy teams must check match with area laws.

Future View for Well-Known Overhead Insulated Cable

The job of covered overhead cables will grow as power companies update grids:- Material Upgrades: New XLPE mixes allow more power flow without bigger wires.

- Weather Toughness: Rising call for cables that take storms, floods, and wild temps.

TDDL Showcases at the 2025 Canton Fair

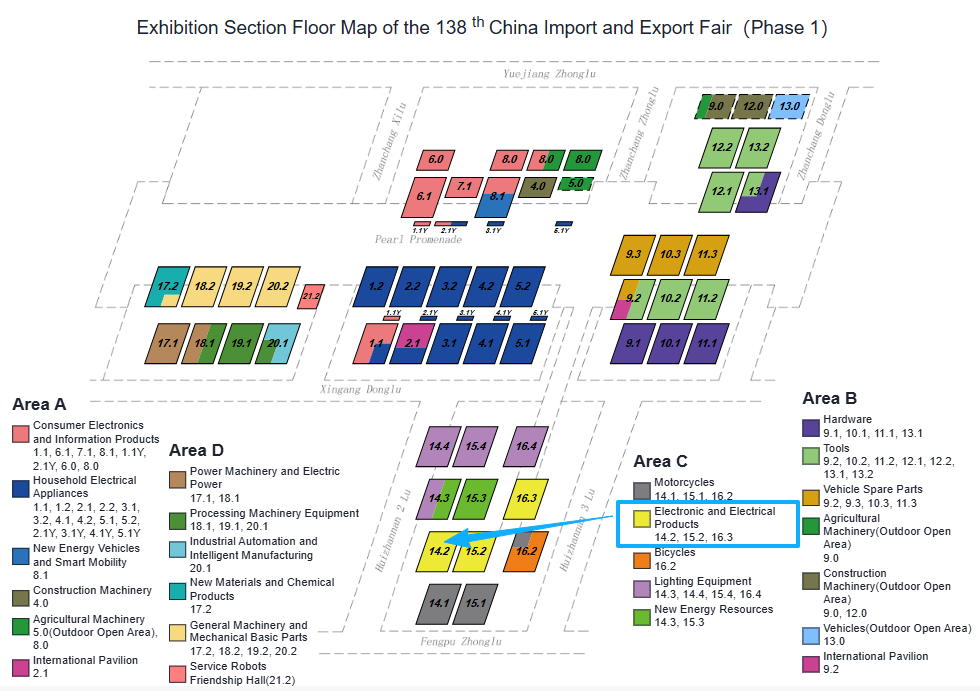

TDDL proudly showcased its advanced overhead insulated cable solutions at the 2025 Canton Fair (October 15–19), drawing attention from global utility buyers and engineering partners. Visitors explored TDDL’s PE and XLPE insulated cable series and discussed how these products meet NFC 33-226 and IEC 60502-2 standards for international power projects.The booth, located at 14.2, 15.2, 16.3 in Area C, featured a complete product display and live consultation area. If you couldn’t attend, you can still contact our sales team to get product brochures or request a virtual meeting.

Conclusion: Why Pick TDDL Well-Known Overhead Insulated Cable

From busy towns to beach spots, well-known overhead insulated cable brings the safety, toughness, and work power companies want. TDDL’s overhead insulated cable options are built to follow IEC 60502-2 and other world standards. That ensures wide use.By picking TDDL’s well-known overhead insulated cable, power companies get:

- Tested safety in many settings

- Long-run money savings

- Sure fit with world rules