May 15, 2025

Why Control Cable is Crucial for Efficient Power Distribution

What is a Control Cable?

What It Is and Its Main Parts

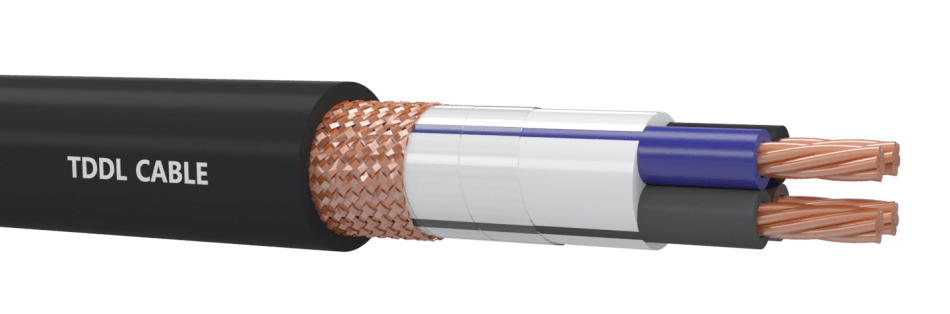

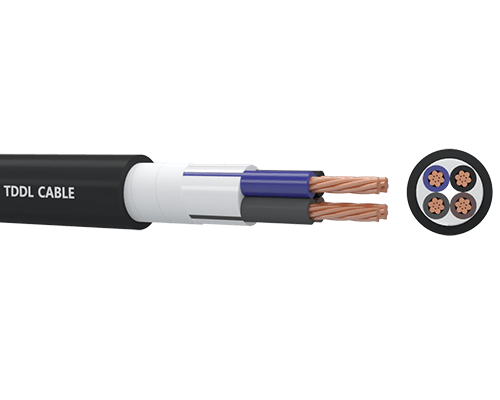

A control cable is a cable used to carry signals to machines, equipment, or systems to be controlled. It is made up of a few simple elements that all work together to help get the signals to their destination points safely without interference. They are conductors, insulation, shielding, and an outer sheath. Conductors, most commonly copper, are used as they are very good conductors of electricity. They're covered in a seal so that there are no unwanted electrical leaks and to seal out external conditions like water or dust. Shielding blocks electromagnetic interference (EMI), something that is important in applications where there is too much electrical hum being detected. And the outer jacket? That's to protect the cable from abrasion, water, or external damage.You’ll find control cables in different types, like multi-conductor cables. These have several conductors, each with its own insulation, all tucked inside one jacket. They’re perfect for jobs that need to send a bunch of signals at once.

How Control Cables Help in Power Systems

Control cables are a big deal in power distribution systems. They let different parts of the system talk to each other. You’ll see them in places like factories, automation setups, power plants, and even transportation. For example, control wires are key for running automated machines. They carry instructions from control panels to things like motors or actuators.In power plants, these cables keep an eye on and manage equipment like turbines or generators. They’re also super important in substations, where they help control things like circuit breakers and switches. Push-pull cables shine in situations where you need precise control over something mechanical from a distance.

What’s the Difference Between Power Cables and Control Cables?

Power cables are all about moving power, often carrying high voltages over long stretches. Control cables, though, are designed to send signals.Control cables usually have extra shielding to block out EMI. That’s a must in places where lots of electrical devices are running at the same time.

Also, power cables tend to have conductors built for handling big currents. Control cables, on the other hand, often juggle multiple signals at once.

Why Control Cables Matter in Power Systems

Keeping Signals Clear and Reliable

Control cables are a must for keeping signals clear in power distribution systems. They’re made to carry the control signals that manage and monitor all sorts of equipment and machines. By making sure every part of the system can communicate properly, these cables help keep things running smoothly and safely.A control cable is built with conductors, insulation, shielding, and an outer cover. The conductors—usually copper —are great at carrying signals because they conduct electricity so well. Insulation keeps those signals from leaking out and protects the cable from things like moisture or dirt. Shielding steps in to block electromagnetic interference (EMI), so signals stay clean even in places with lots of electrical noise. That’s especially crucial in busy industrial settings.

In places like factories or automation systems, control cables are the backbone of automated machinery.

Boosting Efficiency and Performance

Control cables don’t just keep signals clear—they also make power systems work better overall. By giving precise control over machines and equipment, they cut down on downtime and make operations more accurate.Plus, control cables help save energy. By sending accurate signals without any loss or distortion, they make sure systems run at their best without wasting power.

TDDL’s Control Cables: Safe and Budget-Friendly

Top-Notch Safety in TDDL’s Products

TDDL is a standout among control cable makers. Our products meet tough safety standards while delivering awesome performance. We focus on quality at every step of production to make sure our cables meet global safety rules.One big thing about TDDL’s cables is its strong shielding against EMI. That’s super important in industrial settings where electrical interference can mess with signals.

TDDL’s cables also come with sturdy outer covers. These protect against things like scrapes, water, or other wear and tear, so the cables last a long time, even in rough environments.

Safety isn’t just about the design for TDDL.

Quality You Can Afford with TDDL

With advanced equipment and technology, and our factory located in an area abundant in raw materials, we can provide high-quality products at competitive prices.Every production process is strictly inspected to ensure we deliver high-quality cables you can trust.

By focusing on innovation and cost reduction, TDDL has become the preferred choice for power systems seeking reliable control cables.