May 09, 2025

Applications of Medium Voltage Cable in Industrial Settings

Common Uses of Medium Voltage Cables in Industry

Power Distribution and Medium Voltage Cables

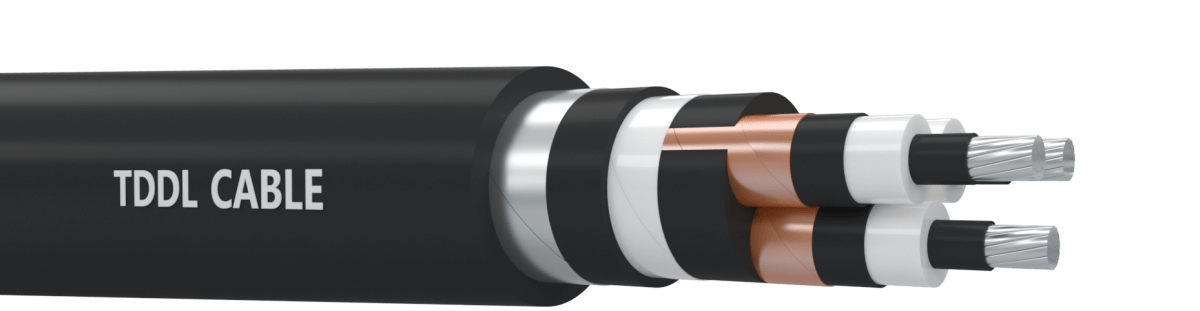

Medium voltage cables are crucial for transferring power where it needs to go in industrial places. They’re made to carry electricity through networks smoothly and reliably. You can use them inside buildings, in tunnels, cable trenches, shafts, or even buried underground. That makes them really flexible for all sorts of setups. They’re tough enough to handle bumps and pulls, which is perfect for places like substations, power plants, or factories.These cables have aluminum conductors, shaped round and packed tight for great conductivity. They’re insulated with cross-linked polyethylene, or XLPE for short. This material keeps insulation strong and reduce energy waste. This means that the cable can safely handle medium voltage and maintain smooth operation. In addtion, their outer layer is polyvinyl chloride, or PVC for short. It can withstand grease, oil, and scratches, so the cables last longer.

Medium Voltage Cables for Motors and Big Machines

Medium voltage cables are a big deal for powering motors and huge industrial equipment. These tasks require a sturdy electrical device that can handle high power without any malfunctions. The powerful electrical and mechanical properties of these cables make them highly suitable for challenging tasks. In factories where large machines are constantly running, these cables can maintain power stability and reduce energy loss. They have a copper tape screen that blocks electromagnetic interference. That’s super important for sensitive equipment. The PVC outer sheath also helps keep the cable strong.Medium Voltage Cables in High-Energy Industries

Mining and Heavy Manufacturing Uses

Heavy industries and mines need medium voltage cables as they use a lot of power. They need cables that can withstand high temperatures, shocks, and vibrations.XLPE insulation in these cables is very good in terms of temperature resistance, and that is perfect for mining conditions at high temperatures. The outer sheath of the cable is flame retardant and oil resistant, which you have an abundance of in heavy industrial plants.

In mining, they provide power for conveyor belts, ventilation systems, and heavy machinery used in digging and crushing ore. Their sturdy insulation keeps things intact and prevents wasting time because of electrical malfunctions.

Heavy manufacturing plants love how these cables handle big energy networks efficiently. They provide power for assembly lines or huge furnaces reliably and meet global safety standards like IEC 60502-2.

The cables use copper tape for screening and non-magnetic steel tape armoring. That makes them very reliable, which is necessary for industries where keeping things running smoothly boosts productivity and profits.

Medium Voltage Cables in Renewable Energy Projects

Wind Energy Systems

Wind energy is a big part of renewable energy, and it needs strong systems to transfer power from turbines. Medium voltage cables are mainly used to connect box transformers and step-up transformers for power transmission. You can lay them indoors, in tunnels, cable trenches, shafts, or underground, they work well in all kinds of places.These cables have round, compact aluminum conductors for better conductivity. The XLPE insulation keeps high resistance and high energy loss, which is the key for long-distance power transmission. The PVC outer layer can resist grease, oil, and wear, making the cables strong enough for harsh conditions at onshore. In offshore wind farms, the cables deal with crazy stress from underwater currents and installation. They’re strong enough to handle external forces and pulling, which makes them perfect. A copper tape screen adds extra reliability by cutting down on electromagnetic interference in high-energy spots.

Solar Power Plants

Solar power plants rely on Solar cable to distribute energy from panels to combiner box. Medium voltage cables are mainly used in PV systems to connect the inverter to the step-up transformer and to transmit power between the step-up transformer and the distribution unit. These cables keep solar systems efficient and safe by handling medium voltage with hardly any loss. Their strong electrical and mechanical features make them a great fit.The cables use non-metallic semi-conducting compounds as conductor screens to prevent electrical faults and improve safety. The XLPE insulation handles heat well, which is crucial for solar setups baking under the sun. The PVC outer layer protects against UV rays, grease, oil, and wear.

In big solar farms with miles of cables, their lightweight but tough design is a win. Aluminum conductors keep the weight down without losing conductivity. Armoring like non-magnetic steel tape or aluminum wire guards against damage during setup or use.

These cables help solar projects grow by spreading energy efficiently over huge areas. They follow global standards like IEC 60502-2, so they’re reliable and safe for renewable energy developers everywhere.

TDDL’s Vision for Medium Voltage Cables by 2025

TDDL’s Cable Innovations

TDDL is a leader in medium voltage cable tech, always improving our products for renewable energy needs. One cool upgrade is pairing XLPE insulation with copper tape screening. This cuts energy loss and keeps insulation strong under different loads.We also make cables for tough environments. Armored cables with aluminum wire or non-magnetic steel tape protect against stress in places like off desert solar plants.

TDDL cares about sustainability, using eco-friendly materials that meet global environmental rules. This reduces the carbon footprint of cable manufacturing and supports renewable energy’s goal of fighting climate change.

The company sticks to strict standards like IEC 60228 and IEC 60502-2. This makes our cables reliable, able to handle high pressure, and low-maintenance—perfect for big renewable energy projects.

Future Plans and Cases

By 2025, TDDL wants to use medium voltage cables in new areas like smart grids and electric vehicle charging systems. As renewable energy grows, smart grids will need advanced cables for two-way power and real-time monitoring. TDDL’s skills can make a big difference here.We also want to support green transport with EV charging networks. Medium voltage cables for this will mix high conductivity with tough mechanical features to handle fast-charging stations.

TDDL plans to research ways to make cables last longer and work better in extreme conditions. We are looking at new materials for better heat resistance and durability while keeping costs down.

As renewable energy keeps growing worldwide, TDDL’s vision shows how crucial medium voltage cables are for a sustainable future. With cutting-edge tech and tough quality standards, TDDL is a go-to for reliable solutions to modern energy challenges.