May 30, 2025

Why Rubber Insulation Cables Are the Way to Go Compared to Plastic

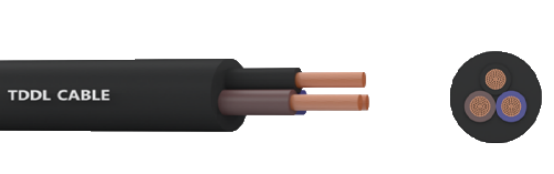

Overview of Rubber and Plastic Insulation Cables

What Are Rubber Insulation Cables?

Rubber-insulated cables are power cables that use rubber-based materials in their protective layers. You’ll find these made with materials like ethylene propylene rubber, natural rubber, or silicone rubber. Here’s why they work so well: they’re tough enough to survive brutal environments.Rubber insulation actually shares the stage with other protective materials, such as oil-soaked paper or mineral-based insulation. But here’s the cool part – rubber’s natural ductility gives it an edge. This ductility makes these cables superstars in scenarios demanding both long-term toughness and heat resistance.

What Are Plastic Insulation Cables?

Plastic-insulated cables take a different insulation material – they rely on materials like PVC, polyethylene (PE), or cross-linked polyethylene (XLPE) for their protective layers. PVC and polyethylene take the lead here. Manufacturers often create specialized versions too, such as flame-retardant types or low-smoke, halogen-free options for particular scenarios.Flexibility and Mechanical Strength

One of the advantages about rubber cables is their flexibility. They’re very suitable for places where cables need to twist or move a lot. Silicone rubber, for example, is super stretchy. It can handle constant stress without cracking or falling apart.Plastic cables are suitable for fixed installation, while rubber cables are suitable for more mobile situations. Rubber cables have good oil resistance, torsion resistance and wear resistance. Plastic cables are easy to process and have good electrical properties. Rubber cables and plastic cables have their own advantages and disadvantages, suitable for different situations.

TDDL’s Rubber Insulation Cables: Quality You Can Trust and Fast Delivery

International Certifications for Material Quality

TDDL’s rubber insulation cables are superior in that they meet difficult international standards of quality in our development history. Cutting-edge manufacturing is used by us to make the products reliable and of high standard. For example, ethylene propylene rubber insulation is world-famous for its high insulation characteristics.High-quality materials make TDDL’s cables durable and safe. Professional tests give customers confidence about the cables’ long-term performance.

TDDL offers a bunch of cable options for different needs. Whether it’s industrial projects needing sturdy cables or outdoor setups requiring environmentally friendly cables, TDDL delivers reliable high-quality products all the time.

Stable and Efficient Delivery Cycles

TDDL not only makes excellent quality products, but also delivers them to you on time. Its smooth supply chain delivers rubber cables worldwide without delays. It is key for projects with tight schedules or big installations.TDDL’s focus on customers goes beyond good products. It offers top-notch service from the first chat to after-sales support. It has made TDDL a trusted name in rubber insulation cables around the world.

The sheath in these cables protects the core from external damage or environmental stress. By combining smart design with fast delivery, TDDL meets customer needs and keeps prices fair.

Rubber insulation cables offer unbeatable perks over plastic ones in durability, reliability, safety, and environmental resistance. Since TDDL has certified quality and dependable delivery, you can trust these cables for your toughest projects.