Aug 07, 2025

How to Identify Reliable XLPE Power Cable Manufacturers for Your Project

(1).jpg)

Check Their Certifications and Standards

Look for Trusted Quality Certifications

A good manufacturer should have certifications like ISO 9001. This means they follow clear rules for quality, risk management, and improvement. Certified companies tend to make reliable, high-quality cables.

Make Sure They Meet Electrical Standards

Check if they follow standards like IEC or ICEA or NFC etc. These ensure cables pass tests for voltage, insulation, and flame resistance etc. It’s a sign of dependability.

Look at Product Quality and Specs

Know What’s in XLPE Cables

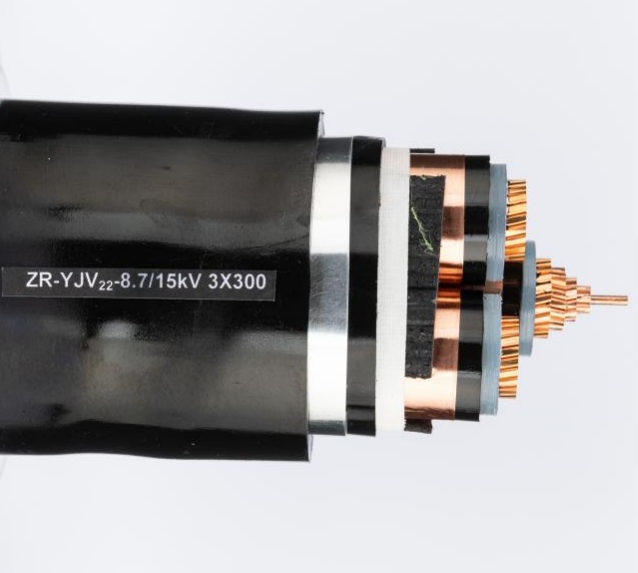

XLPE insulated cables use chemically cross-linked XLPE material for medium-voltage power cables, manufactured with three-layer CCV production technology. For low-voltage power cables, silane cross-linked polyethylene insulation material is used, processed through steam cross-linking technology. Appropriate materials are selected according to the voltage rating to ensure the cable’s insulation performance. The conductor can be copper, aluminum, or AA-8000, depending on the required current-carrying capacity.

Check Electrical Performance

The rated voltage and insulation material should be matched. The long-term operating temperature of XLPE insulation is 90℃.

Review Their Production Skills

Check for Testing Labs

A solid manufacturer has its own labs to test every batch. They check things like conductor resistance, insulation thickness, and aging resistance at each step. They also test XLPE insulation for mechanical and physical properties and electrical performance.

Look at Their Factory Setup

The factory uses modern equipment for production and testing to ensure both capacity and quality. This ensures that large orders can be fulfilled on time while meeting the required product quality standards.

See If They Can Customize

Products can be customized according to specific requirements. For needs such as water-blocking, flame-retardant ratings, or other special specifications, the factory adjusts the process design accordingly.

Dig Into Their Experience and Reputation

Check Their Track Record

Experience counts in cable-making because it’s tricky. Companies with years in the game often share examples of big projects they’ve done, showing they’re reliable.

Look for Customer Feedback

Reviews from clients, like utility or construction companies, show how cables hold up in tough conditions. Awards or recognition are a bonus.

Read Online Reviews

Check forums or procurement sites for honest feedback. These can reveal issues like late deliveries or uneven quality that brochures might hide.

Check Their Support Services

Look for Installation Help

Reliable manufacturers give clear guides for installing cables, especially for armored or underground ones where bending matters. They also offer technical help.

Review Warranties and Returns

Look for warranties from 12 months to 5 years. Clear return policies show they trust their cables’ durability.

Test Their Responsiveness

Quick answers to technical questions are crucial during projects. Check if they offer direct phone or email support with knowledgeable staff.

FAQ

Q: How can I check if a manufacturer's XLPE cables are right for my specific industry?

A: Ask the maker for full product technical specification date. Ask for samples to test yourself. Or, talk to an electrical engineer. They can confirm the cables fit your project's technical needs.

Q: What questions should I ask a manufacturer when we first talk?

A: Ask about the cable structure, dimensions, and performance. Find out their lead times. Ask if they can customize the cables. See how they fix quality problems. Ask for examples from similar jobs. Also, ask about their tech support team. How easy is it to get help?

Q: How do I know if a manufacturer's price is fair?

A: Get quotes from several different makers. Don't just look for the cheapest price. Focus on the quality of materials and the specs. Check if these costs match what's normal in the business for similar cables.