May 23, 2025

Understanding Building Wire: Key Features and Applications Explained

What Is Building Wire

What’s Building Wire All About?

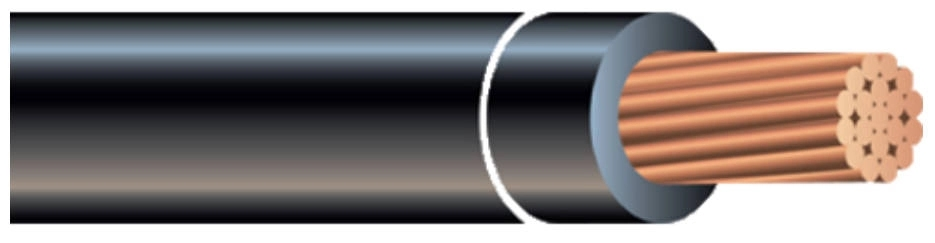

Building wire is just a fancy name for the electrical cables that carry power inside homes, offices, and factories. Its job? To safely move electricity from the main power source to things like lights, outlets, and appliances. These wires are built to handle certain voltage levels and follow safety rules to keep electrical mishaps at bay.Types of Building Wire You’ll See

There are a few common types of building wires, each made for specific jobs:- THHN/THWN Wire: This one’s got a PVC layer with a nylon cover for extra toughness. It can handle up to 600 volts. You’ll spot it in homes and businesses all the time.

- Bare Conductors: These wires don’t have any insulation. They’re used for high-voltage stuff or as grounding wires, often made from copper or aluminum.

- Cross-Linked Polyethylene (XLPE) Wires: These are super tough and great at handling heat, so they’re perfect for rough environments.

What Makes Building Wire Special

Materials That Matter

The stuff building wires are made of is a big deal:- Copper: Copper’s a rockstar at conducting electricity. It doesn’t rust easily and is super easy to work with. Only silver beats it for conductivity, and it’s not magnetic either. Copper alloys can make it even stronger and more durable.

- Aluminum: It’s not as conductive as copper, but it’s light and budget-friendly. Adding alloys makes it stronger while still doing the job.

- Steel: Steel’s used to beef up wires or for grounding because it’s really strong.

Insulation and Outer Layers

The insulation and outer coatings keep wires safe from things like water, heat, or getting banged up:- PVC Insulation: It’s flexible and shrugs off chemicals.

- Nylon Jackets: These add a layer to protect against scratches or wear.

- XLPE Insulation: This can take serious heat without breaking a sweat.

Voltage and Power Capacity

Building wires come with voltage ratings that tell you how much power they can safely handle:- Take THHN/THWN wire—it’s good for up to 600 volts.

- How much current a wire can carry depends on its size, material, insulation, and how it’s set up.

Where Building Wire Gets Used

Wiring Up Homes

In houses:- These wires power up lights, outlets, air conditioners, and more.

- THHN/THWN is a go-to because it’s versatile and meets safety standards.

Offices and Factories

In office buildings:- Wires need to support heavy-duty gear like elevators, air systems, or computers.

- They’ve got to stand up to crazy heat or harsh chemicals.

- XLPE-insulated wires are often the pick here since they’re so tough.

High-Risk Spots

In places where safety’s a big concern:- You’ll see specially designed or armored wires.

- For example, high-voltage lines might use bare wires. Some cables are fire-resistant or can even work underwater or underground.

Following the Rules for Building Wire

Why Certifications Matter

Certifications are a huge deal in the building wire world. They prove the wires meet strict safety, quality, and performance standards. Certified wires go through tough tests to make sure they follow national and global rules. This gives everyone confidence that electrical setups will be safe.Wires like THHN/THWN are certified to handle their rated voltage and insulation needs. This means they won’t give out under pressure. Using certified wires cuts down on risks like short circuits or fires.

Plus, certifications make things standard across the industry. They ensure all parts of an electrical system play nice together, making installation and repairs easier. For companies like TDDL, getting certified shows we are serious about quality.

Safety Rules for Wiring

Sticking to safety rules is a must to avoid accidents and keep wiring systems running for years. Regulatory groups set out guidelines for materials, designs, and how to install wires to dodge hazards.Building wires need solid insulation and the right voltage ratings to meet these rules. For instance, THHN/THWN wires have PVC insulation and nylon jackets to fend off moisture and wear.

Safety rules also call for certain materials. Copper’s a favorite because it conducts so well and doesn’t rust. Aluminum alloys are another option—they’re strong but won’t break the bank.

By following these standards, manufacturers make sure their wires help create safe electrical systems for homes, offices, and factories.

TDDL’s Top-Notch Building Wires

High-Quality Materials That Last

TDDL’s building wires are made with the best materials to ensure they perform well and stick around. Copper’s a big player here because it’s awesome at conducting electricity. Copper alloys make it even better by boosting resistance to wear, rust, and stress. That makes it perfect for jobs needing steady power over time.Aluminum’s also in the mix. It’s lighter than copper, though not as conductive. Alloys give it extra strength for certain setups.

TDDL uses top-tier insulation to keep wire products safe from damage. PVC insulation is flexible and fights off chemicals and moisture. Nylon jackets add another layer to guard against scratches or dents.

These wires aren’t just tough—they stay reliable no matter the conditions, making them great for all sorts of uses.

Certified Wires That Meet Standards

TDDL’s certified wires meet tough national standards, proving they’re all about safe, solid solutions. For example, our THHN/THWN wires hit the mark for voltage and insulation quality. This means they can tackle demanding jobs without any safety worries.TDDL uses cutting-edge manufacturing to keep every wire consistent. From picking high-quality copper or aluminum to running strict tests during production, we have got every step covered.

By offering certified wires for everything from home wiring to industrial projects, TDDL shows it’s a name you can trust in the electrical world.

FAQ

Q: What exactly is building wire?

A: Building wire is the electrical cable used to carry power inside buildings like homes, offices, or factories. It safely moves electricity from the main power source to things like lights, outlets, and appliances, all while meeting safety standards to avoid electrical problems.Q: What are the most common types of building wire?

A: You’ll typically see these types:- THHN/THWN Wire: Has PVC insulation with a nylon cover, handles up to 600 volts, and is super common in homes and businesses.

- Bare Conductors: No insulation, used for high-voltage tasks or grounding, often made of copper or aluminum.

- XLPE Wires: Tough, heat-resistant wires great for harsh environments.

Q: What materials are building wires made from?

A: The main materials are:- Copper: Awesome for conducting electricity, doesn’t rust easily, and is easy to work with.

- Aluminum: Lighter and cheaper than copper, often mixed with alloys for extra strength.

- Steel: Used to make wires stronger, especially for grounding.

Meta keywords: buliding wire, wire products, TDDL, cable products

Meta Title: What Are the Key Features and Applications of Building Wire?

Meta Description: Explore building wire: types (THHN/THWN, XLPE), materials (copper, aluminum), uses in homes and offices, and safety standards