Dec 11, 2025

UNE HD 620 S3 Standard Explained: Structure, Testing Requirements, and MV Cable Compliance

UNE HD 620 S3 covers many specifications, the following is an introduction to RH5Z1: what it covers, why certain rules exist, and how the testing process usually plays out in real projects.

1. What Is RH5Z1Cable (UNE HD 620 S3)

UNE HD 620 S3 is applicable to Europe and the Americas. This standard covers a wide range of medium-voltage cable structures, including structural dimensions, electrical performance, mechanical performance, and installation methods. Due to the large number of product structures, this example will primarily focus on the RH5Z1.RH5Z1 comes in four structures.

- Type 10E-6: Single-core polyolefin sheathed cable, no flame retardant requirements.

- Type 10E-7: Single-core polyolefin sheathed cable, minimum CPR rating Eca.

- Type 10E-8: Single-core polyolefin sheathed cable, minimum CPR rating Cca-s1b,d2,a1。

- Type 10E-9:Multi-core polyolefin sheathed cables with steel carrier are used in overhead and power distribution systems.

2. Required Cable Structure

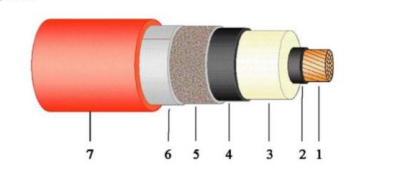

The basic structure of the RH5Z1 product is as follows:2.1 Conductors

Aluminum or copper. Class 2 compacted round, dominates for cost and weight reasons. Aluminum is the most common conductor material, while copper conductors are less common. The appropriate specification should be selected based on factors such as current carrying capacity and installation conditions. The conductor must meet strict resistance and dimensional tolerances. If water resistance is required, TDDL cable chooses to use semi-conductivity water-blocking tape to meet the requirements.2.2 Insulation

Conductor screen and XLPE insulation and insulation screen are produced using a CCV production line and extruded in a single process, maintaining excellent electrical performance.2.3 Water blocking tape

If water resistance is required, TDDL cable chooses to use semi-conductivity water-blocking tape to meet the requirements.2.4 Metallic Screening

The material uses longitudinally wrapped aluminum-plastic composite tape with a nominal thickness of 0.3mm and an overlap width of not less than 5mm. It meets the requirements for shielding grounding protection and radial water resistance. The metal shield must be bonded to the sheath.2.5 Outer Sheath

The polyolefin sheath is UV resistant, abrasion resistant, low smoke, and halogen-free.

1 Conductor 2 Conductor screen 3 Insulation 4 Insulation screen

5 Water blocking tape 6 Metallic Screening 7 Outer Sheath